The Plan of St. Gall a study of the architecture & economy of & life in a paradigmatic Carolingian monastery |

| II. |

| V. |

| V. 1. |

| V.1.1.. |

| V.1.2. |

| V.1.3. |

| V.1.4. |

| V. 2. |

| V.2.1. |

| 10. |

| 10. |

| V.2.2. |

| V. 3. |

| V.3.1. |

| V.3.2. |

| V.3.3. |

| V. 4. |

| V.4.1. |

| V.4.2. |

| V.4.3. |

| V. 5. |

| V.5.1. |

| V.5.2. |

| V. 6. |

| V.6.1. |

| V.6.2. |

| V.6.3. |

| V.6.4. |

| V. 7. |

| V.7.1. |

| V.7.2. |

| V.7.3. |

| V.7.4. |

| V.7.5. |

| V.7.6. |

| V. 8. |

| V.8.1. |

| V.8.2. |

| V.8.3. |

| V.8.4. |

| V.8.5. |

| V.8.6. |

| V.8.7. |

| V.8.8. |

| V. 9. |

| V.9.1. |

| V.9.2. |

| V.9.3. |

| V. 10. |

| V.10.1. |

| V.10.2. |

| V.10.3. |

| V.10.4. |

| V. 11. |

| V.11.1. |

| V.11.2. |

| V.11.3. |

| V. 12. |

| V.12.1. |

| V.12.2. |

| V.12.3. |

| V. 13. |

| V.13.1. |

| V.13.2. |

| V. 14. |

| V.14.1. |

| V.14.2. |

| V. 15. |

| V.15.1. |

| V.15.2. |

| V.15.3. | V.15.3 |

| V.15.4. |

| V. 16. |

| V.16.1. |

| V.16.2. |

| V.16.3. |

| V.16.4. |

| V. 17. |

| V.17.1. |

| V.17.2. |

| V.17.3. |

| V.17.4. |

| V.17.5. |

| V.17.6. |

| V.17.7. |

| V.17.8. |

| V. 18. |

| V.18.1. |

| V.18.2. |

| V.18.3. |

| V.18.4. |

| V.18.5. |

| VI. |

| VI. 1. |

| VI.I.I. |

| VI.1.2. |

| VI.1.3. |

| VI.1.4. |

| VI. 2. |

| VI.2.1. |

| VI.2.2. |

| VI.2.3. |

| VI.2.4. |

| VI. 3. |

| VI.3.1. |

| VI.3.2. |

| VI.3.3. |

| VI. 4. |

| VI.4.1. |

| VI.4.2. |

| VI.4.3. |

| VI. 5. |

| VI.6. |

| The Plan of St. Gall | ||

V.15.3

THE MORTARS

MAN- OR WATER-POWERED? CONFLICTING VIEWS

The crushing devices designated by the term pilae, i.e.,

"pestles," in the house lying west of the Mill (fig. 438),

raise the same problems posed by the milling apparatus.

Were they operated by hand or water? Keller, in this case

too, took the first position. He drew attention to two old

hand-operated mortars which he discovered in the remote

village of Beltis on the lake of Wallenstadt in Switzerland

(fig. 449 A.1, A.2).[503]

One was three feet high, cut out of a

solid trunk of oak, with the interior hollowed out conically.

The pestle, likewise, was made of a single piece of oak,

except for its handle, and was studded with nails at its

base. This, Keller thought, must have been the contrivance

that the drafter of the Plan of St. Gall had in mind when

he drew his peculiar L- or key-shaped pilae (fig. 438).

451. HOKUSAI. JAPANESE TRIP-HAMMER (19th cent.)

[after Singer, Holmgard, Hall, II, 1956, 107, fig. 71]

If his expression of grim determination is an indication, the man acting as

counterweight to the hammer could scarcely have worked harder using a mortar

and pestle for his task.

That instruments of the Beltis type were used during the

Middle Ages is beyond question, and easy proof of this

may be found inter alia in a delightful marginal drawing

of the Luttrell Psalter (fig. 449C), which shows a bearded

cook pounding a huge mortar with a pestle almost twice

his own height.[504]

The mortar, apparently made of iron or

bronze, reaches to slightly above the knee of the pounding

cook, and by that criterion should have been meant to have

a height and width of roughly two feet. The largest implement

of that type I have ever examined is a mortar carved

of a single block of stone, that stands now in the medieval

granary of the Abbey of Le Thoronet in Provence, only a

few yards away from the millstone discussed in an earlier

part of this chapter. This mortar (fig. 449B) has a round

base, 2 feet in diameter, is 3½ feet high, and 4 feet wide at

the top. Its pounding cavity tapers from the rectangular

opening at the top to a conical form at the bottom. The

pestle—which does not look to me to be the original—is

a roughly hewn trunk of a young tree, about 9 inches thick

me that it could be worked with some effort by a single

man, and with ease by two men lifting it in conjunction.

Yet I would be inclined to think that in the Middle Ages

mortars and pestles of this order of magnitude were water

driven, rather than hand-operated mechanisms. This was

also the view of Rudolf Meringer who has made a special

study of this type of instrument. In an article on the implements

of the pinsere series and their names, published in

1909, Meringer[505]

drew attention to the fact that the pilae

of the Plan of St. Gall (fig. 438) were not only considerably

larger than those with which they had been compared by

Keller (fig. 449A) but also of vastly different shape. He

claimed that, rather, they bore striking resemblance to a

type of crushing device which in German is called Anke,

and illustrated his views by a startling juxtaposition of the

pilae of St. Gall and a drawing of a modern water-driven

iron hammer (fig. 453).[506]

The earliest pictorial representation

of a water-driven recumbent western tilt-hammer

appears to be a woodcut in Spechthart's Flores Musicae,

published in 1488 (fig. 455).[507]

In an earlier period this contrivance

was operated by hand or foot, as it was still in very

recent times in Galicia (fig. 450), Poland, China, and

Japan in very much the manner in which this is depicted

in a whimsical drawing by the Japanese painter Hokusai

(fig. 451). Man-powered tilt-hammers of this type, as was

subsequently shown, were used in China in remote periods,

and their design and mode of operation is well attested by

two small models in green glazed pottery from the Han

period (206 B.C. to A.D. 220) which are now in the Nelson

Art Gallery (fig. 452A-C), Kansas City, as well as a Han

moulded brick found at P'en-shan Hsien, in the Szechuan

Provincial Museum, Chengtu (fig. 452D).[508]

Meringer

was convinced that the pilae of the Plan of St. Gall

did not belong to the foot-operated type, but that they were

water driven, and he attempted a reconstruction (fig. 454),

in which the pestle beams were alternately lifted and

released for fall by the cogs of a cylindrical drum mounted

directly upon the axle of a water wheel, as in the modern

iron hammer (fig. 453). Hydraulic trip-hammers of this

or a similar design are attested for China through unequivocal

literary descriptions as early as the reign of Emperor

Wang Mang (A.D. 9-23) and through less reliable sources

perhaps even as early as the third century B.C.[509]

Meringer

could not prove that the camming action employed in this

device was known in Carolingian times,[510]

and his interpretation

of the pilae of St. Gall as hydraulic cam-operated

pounding mechanisms did not come to the attention of

Marc Bloch who, in his classical and widely read study on

the advent and spread of the water mill, referred to the

pilae of St. Gall as "a crushing instrument which, on the

plan, was certainly not shown as being water driven;"[511]

a view which was reiterated in 1954 by Bertrand Gille,[512]

and subsequently adopted, although perhaps not with the

same degree of conviction, by Lynn White in 1962.[513]

Finally, in 1965, it looked as though Meringer's interpretation

had received a final blow, when Joseph Needham,

in his monumental Science and Civilization in China, after

a thorough account of the Chinese history of the hydraulic

trip-hammer[514]

advanced the theory that this mechanism

was introduced in Europe "about the time of Marco Polo,"

in connection with the fulling trade when much other

Chinese textile machinery appears to have made its way to

Europe. Needham proclaimed that all water powered European

stamp mills prior to that period were machines in

which pestle beams moved in vertical action in the manner

illustrated by a drawing made by an anonymous Hussite

engineer around 1430 (fig. 456).[515]

Meringer, 1909, 24ff a study that was brought to my attention by

Lynn White years ago, when I first concerned myself with this problem.

I am greatly obliged to Lynn White for having subsequently kept me

apprised of other publications bearing on this subject.

Meringer had, in fact, already established this comparison two

years earlier; see Meringer, 1907, 285, figs. 8 and 9.

On water-powered Chinese trip-hammers see Needham, op. cit.,

392. The earliest printed illustration of this mechanism is in the Nung

Shu of 1313 A.D. See Needham, op. cit., 395.

On cams and camming action in general see Lynn White, 1962,

79, 81 and 128ff as well as Needham, op. cit., 83, 84 and 384-85.

Bloch, 1935, 543: "Un instrument de broyage qui, sur le plan,

n'était certainement pas mû par l'eau."

Munich, National Library, Ms. Cat. 197, fol. 10r. See Beck,

1899, 279ff. Cf. below, p. 248, n.67, on the date of the ms.

EVIDENCE FOR WATER-POWERED TRIP-HAMMERS

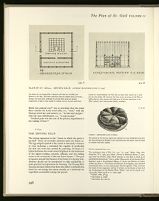

The Plan of St. Gall contradicts these views. The pilae

of its Mortar House can under no circumstances be interpreted

as vertical pestles. Their design—a hammer attached

at right angles to a pestle beam connecting at the opposite

end with a body of cylindrical shape—leaves no doubt

that they were recumbent hammers activated by the cams

of a revolving drum. Their dimensions as well as their

location, next to a water-driven grain mill, suggests that

they were water powered. The pestle beam alone is 10 feet

long (4 standard modules), the hammer has a length of 6

feet (2½ standard modules) and the drum has a diameter

of 6¾ feet. The over-all length comes close to 17½ feet. This

is a very heavy piece of equipment that could not possibly

be operated by hand or foot. The Plan may somewhat

exaggerate the dimensions of the drum,[516]

but it leaves no

452.A MODEL. FARMYARD DETAIL WITH FOOT-OPERATED TRIP-HAMMER. HAN DYNASTY, 206 B.C.-220 A.D.

IRRIDESCENT GREEN GLAZED POTTERY, 8¾ × 6 × 2½ INCHES

only within the context of a water-powered apparatus.

Marc Bloch's argument that water is not shown on the

Plan, does not militate against this conclusion. We have

shown in our chapter on omissions and oversights how

waterways, although nowhere in evidence on the Plan,

could be a determining factor in siting of facilities dependent

on this power source, and were therefore clearly a

possibility taken into account by the designing architect.[517]

The crushing mechanisms of the Mortar House of the

Plan of St. Gall are, as far as I can see, the earliest historical

evidence of the use of hydraulic trip-hammers in Western

Europe. Their appearance on the Plan makes it clear that

water-driven trip-hammers were, at the time when the

original scheme was drawn, i.e., in 816-817, considered

standard equipment of a paradigmatic Carolingian monastery.

There is no reason to presume that the inventor of the

scheme was also the inventor of the mechanism. The

system as such may, even in Europe, have been of considerably

greater age. It may have been diffused in Frankish

times from China, as the stirrup certainly was, as the two

forms of modern horse-harnesses probably were, and as

the mechanical crank may have been.[518]

Yet even that is highly doubtful. We have shown in our chapter on

the Scale and Construction Method Used in Designing the Plan that the

author of the original scheme of the Plan was acutely aware of the

realities involved in his scaling of objects. It is possible, nevertheless that

minor distortions were brought into the drawing when the Plan was

copied. Small objects tend to be drawn slightly enlarged as they are

traced. The odd dimension of 6¾ feet of the hammer head and drum may

in the original scheme have been 5 feet.

Lynn White, 1962, 1-2, 14-28, 139-46 (stirrup), 59-61, 67-69,

156-57 (harness) 79, 81, 128ff (crank). Needham, op. cit., 317 note e

(stirrup), 304-28 (harness), 111-19 (crank).

A SURVIVING MEDIEVAL HYDRAULIC TRIP-HAMMER

I feel strengthened in this conjecture by the circumstantial

historical evidence surrounding a water-powered

medieval trip-hammer that came to my attention, in the

summer of 1970, while travelling in the mountains of the

province of León in Spain. This mechanism, not only

intact but able to be operated, is housed in a smithy located

in the valley of Compludo, on the grounds of a former

monastery of that name. San Fructuosus, a Visigoth of

royal blood and the founder of Spanish monachism, established

Compludo as the first of a vast web of monasteries.

The trip-hammer owes its anachronistic survival to the

452.B

The processing of grain for domestic use

in China during the centuries just before

and after the birth of Christ in the West

reveals wholly familiar technologies and

associations. The model of the farmyard

(fig. 452. A) contains, in addition to the

trip-hammer, a small mill and what

appears to be a parching kiln built into an

enclosure wall—an association also

reflected in the Plan of St. Gall, some 6

centuries later.

The trip-hammer in the model (figs.

452.A-B) was the simplest of mechanisms;

in it is applied the principle of fulcrum

and lever actuated by direct force.

452.C

WILLIAM ROCKHILL NELSON GALLERY OF ART, ATKINS MUSEUM OF FINE ARTS, KANSAS CITY, MISSOURI

IRRIDESCENT GREEN GLAZED POTTERY, 10¾ × 3½ × 3½ INCHES

is accessible by only a stony mountain road whose narrow

and precipitous course offers to the unexpecting modern

visitors moments of breathtaking suspense.[519] The instrument

is described by Florentino-Augustin Diez Gonzáles,[520]

in a study of the political and social life of the Spain of San

Fructuosus, which also includes a sketch of this unusual

mechanism.[521] It conforms in all respects to the trip-hammer

shown in Spechtshart's woodcut of 1488 (fig. 455)

and the modern specimen discussed by Meringer (fig. 453),

except that it is considerably larger.

The water that sets the Compludo hammer into motion

is channeled from the confluence of two narrow mountain

streams, the Miera and the Miruello, into a collecting

basin (banzao) from where it falls upon the heavy wooden

studs of a waterwheel. This wheel, 8 feet in diameter, is

driven by a shaft (árbol) made of chestnut, 16 feet long

and 2½ feet thick. Rotating horizontally this timber,

hardened by age like stone, activates with its wooden cogs

452.D CHENGTU, SZECHUAN, PROVINCIAL MUSEUM

RUBBING, CLAY TOMB TILE, (46 × 28cm) DETAIL, EASTERN HAN PERIOD, 23-220 A.D.

[after Liu Chih-yuan]

Two men are shown pounding rice with trip-hammers, a scene of daily life of the lower social strata of Chinese society that artists of the

Eastern Han loved to portray.

The tile was excavated in 1956 at T'ai-p'ing-hsiang, P'enghsien, Szechuan Province. It was published in Ssu-ch'uan Han-tai hua-hsiang

pei-t'o p'ien (Portfolio of Han Dynasty Impressed Clay Tiles from Szechuan), Ssu-ch'uan sheng po-wu-kuan (Szechuan Provincial

Museum) by Shang-hai jen-min mei-shu ch'u-pan she (Shanghai People's Art Press), 1961, pl. 3, from which this detail is taken.

453. MODERN TILT-HAMMER (SCHWANZHAMMER)

PLAN AND SIDE ELEVATION

[redrawn after Meringer, 1907, 285, fig. 10]

The cam block driving the hammer can be linked to a drive system

as sophisticated as one powered by steam, or as simple as one driven

by an animal on a treadmill.

smashing hammer (mazo) rises and falls. The rhythm or

beat of the stamp can be controlled from within the forge

by a second mechanism that augments or decreases the flow

of the water turning the wheel, as the varying nature of the

work requires (sketched roughly in Gonzáles's drawing).

The ore is smelted in the furnace by a fire fanned to intense

heat by means of air drafted into it by hydraulic action

(shown in the background of Gonzáles's sketch) and under

the beat of the hammer, converted into malleable iron.[522]

To watch this primordial mechanism in operation was

truly an awe-inspiring experience.

The valley of Compludo lies in the Montes de León some 23 km.

southeast of the city of Ponferrada. It is not shown on the Mapa Oficial

de Carreteras (scale 1:400,000) of Spain. To reach it one must travel from

Pontferrada to the mountain villages of Molinaseca, Riego de Ambroz and

Acebo; and from the latter in precipitous descent (only advisable to

motorists with experience in rough mountain travel) to the completely

isolated valley of Compludo, formed by the confluence of two narrow

mountain streams, the Miera and the Miruello which shed their water

into the Boeza River. The scenery is of outstanding beauty.

Florentino-Augustin Diez González, "Notitias de la vida políticosocial

de la España de San Fructuoso," in San Fructuoso y su tiempo,

1966, 7-57.

The drawing in Gonzáles's article, while portraying operational

details of the smithy of Compludo with great veracity, is not quite

realistic in its perspective. The trip-hammer is not longer, but 3 feet

shorter than the tree by which it is activated and the diameter of the

waterwheel is greater than appears on the drawing (cf. Horn, 1975, 245).

I do not know at what time in history water pressure was first used

to blow air into furnaces. Lynn White, in a recent essay on "Medieval

Uses of Air" does not make reference to the existence of any such

systems (Lynn White, 1970, 92-100).

MONASTIC ECONOMY AND WATER POWER

UNDER ST. FRUCTUOSUS

The date of the hammer is unknown.[523]

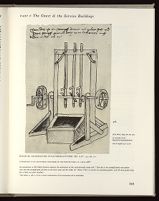

Local tradition PERSPECTIVE VIEW [redrawn after Meringer, 1909, fig. 35] Meringer interpreted the two trip-hammers of the Mortar House of

ascribes it to "Romanesque period" (edad romanica).

454. PLAN OF ST. GALL. TILT-HAMMER

the Plan as being activated by a cam block formed on a single

timber extending, as part of an axle shaft, from the hub of the

waterwheel.

have been an integral part of the monastic economy of the

time of San Fructuosus (d. 665).[524]

This view is not so

455. SPECHTSHART. FLORES MUSICAE

STRASSBOURG, 1488, fol. 7v

[courtesy of the University Library, Freiburg i. Br., Germany]

The woodcut shows an iron forge with a water-powered tilt-hammer

activated by a cylindrical cam block mounted on the axle of a waterwheel.

Two blacksmiths forge iron on an anvil with the hammer's

aid; behind them Pythagoras weighs hammers. In the background,

Tubal chisels musical notes into a column, representing Pythagorean

philosophical preoccupation with order, number, and harmony of the

spheres of the Ptolemaic universe (cf. I, 231, fig. 187).

seventh century, as has been shown in the preceding

chapter, was the great century of systematic application of

water power to milling in the economy of coenobitic

monachism.[525] The development was spurred by the need to

provide great quantities of flour for the sustenance of large

numbers of men whose religious activities required that they

be freed from certain common forms of labor, in order to

devote themselves to the more serious task of serving God

in prayer and chant. It is not an unreasonable conjecture

that the same need may also have fostered the invention or

adoption of the cam which made it possible to harness water

for tasks requiring the crushing blow of a rising and falling

mechanical hammer. It is quite possible that this idea (or

its adoption) was first conceived in connection with iron

works where the brutal blow of a hydraulic stamp offered

advantages highly superior to those that could be derived

from its use in the lighter task of crushing grain or of

fulling cloth. The banks of the rivers in the mountains of

Eastern Leon, where San Fructuosus founded his first

monasteries, carry iron deposits important enough to be

mentioned by Pliny the Elder and other Roman writers;[526]

numerous localities in this area, now in ruins or deserted,

carry even today the name herrería (iron forge).[527]

The Fructuosan monastic economy formed an ideal

ambiance for the invention of such a power mechanism. It

created a sudden and vast demand for agricultural tools by

converting virtually overnight deserted valleys into densely

populated rural communities, formed not only by the

multitude of monks that settled in the monastery itself, but

in addition by a veritable army of secular followers who

were allowed to establish themselves as tenants in the vast

stretches of land which the monastery owned in the valleys

and mountains around it. Among them were members of

the former household of San Fructuosus (whose paternal

inheritance was enormous), magnates from the royal court

with their entire families, soldiers from the Visigothic

army who fell under the spell of the saint, and in a mystical

commotion that had no precedent, followed him in such

numbers that their chieftains found themselves compelled

to legislate against such wholesale desertion of the army

and flight into the country.[528]

A blacksmith capable of

converting ore into iron with the aid of water power and

shaping it into usable tools could meet the demands created

by such a sudden population increase in the country, and the

456. MUNICH, BAYERISCHE STAATSBIBLIOTHEK. MS. LAT. 197, fol. 10r

ATTRIBUTED TO AN ANONYMOUS ENGINEER OF THE HUSSITE WARS, CA. 1472-1486[529]

An annotation in Old High German explains the mechanism of this vertical-pestle stamp mill: "Item das is ain stampff damit man pulver

stost unn dye stampff gent all drey in ain loch, ainer auf der ander ab" (Item: This is a mortar for pounding powder, and all three pestles drop

into a hole, one after another).

VALLEY OF COMPLUDO, LEÓN, SPAIN. MEDIEVAL IRON FORGE & WATER-POWERED TRIP-HAMMER,

WITH FORGE BLOWER ASSOCIATED WITH FLUME. Date of the initial installation unknown,

concept possibly dating from Visigothic period. See caption above.

457.A

PERSPECTIVE VIEW

In 1975 we paid another visit to the Compludo

forge and discovered that the trip-hammer we

first inspected in 1970 was being rebuilt, and the

waterwheel replaced by a slightly sturdier one.

The hammer had been moved to the outside yard

to serve as a template for its replacement. The

sturdy cammed trunk, strongest member of the

mechanism and subject to great torsional strain,

was considered in good enough condition to serve

another span in the life of the hammer. It had

earlier been reinforced lengthwise by iron bars

banded to it with iron hoops.

The carpenter directing the work was convinced

that in continuous use, wheel and hammer would

need replacement every 40 years, the main trunk

every century. He shared local belief that the

mechanism is medieval and would tend to retain

its original design for a virtually indefinite span

of time, even though its components were

periodically renewed.

These drawings were made with aid of measurements

taken in 1975. They do not show the

apparatus governing the flow of water to the

wheel and thus the speed of the hammer's

action. For rough sketches of that mechanism

and the means by which air is drafted into the

forge furnace, a function also associated with the

flow of water to the wheel race, we still depend

exclusively on the drawing published by

Gonzáles (1966, 46) and reproduced by Horn

(1975, 245).

457.B

457.C

457.D

to the adoption of devices facilitating their production.

The Romans, it is generally conceded, did not make any

use of water-powered trip-hammers transmitting the

rotational movement of the wheel and its axle into the

vertical beat of a recumbent hammer by means of cogs.

China, unquestionably is the prime inventor. But the Plan

of St. Gall attests that at the beginning of the ninth century

such mechanisms were, even in the West, well known and

widely employed. This seems to vitiate the theory of its

westward diffusion by Marco Polo and suggests that the

knowledge of this invention came to Europe in the wake of

contact established with the Far East, in the fourth and

fifth centuries A.D. by the invasion of the Huns and other

Asiatic tribes, with whom the Visigoths were in close, and

often mortal, association over long periods of time.

In an earlier study (Horn, 1975, 254 note 13) I expressed the hope

that radiocarbon analysis of the timbers of axle, hammer, and waterwheel

might in the future help establish the age of the hammer. Returning to

the site in 1974, I discovered that all these timbers were in process of

being replaced. The carpenter in charge of the work held the view that

because of the heavy strain imposed upon these members when in daily

operation, such repairs would have to be made every 40 to 50 years. This

does not militate against the assumption of a medieval origin for the

mechanism on this site.

"La [herrería] de Compludo signe siendo un monumento vivo, casi

intacto, que bien pudo connocer los tiemposos frutusianos." Gonzáles,

op. cit., 44.

Gonzáles, loc. cit., lists one in the vicinity of Vega de Valcarce;

another one in Puente Petra (near Oencia); a third one in Marciel (near

Quintana de Fuseros) which gave its name, Ferreria, to a village that has

since disappeared; a fourth one in Paradaseca. In a fifth, the herreria of

Montes (near San Clemente de Valdueza) the stamping mechanism is so

well preserved as to permit its reconstruction.

For more detail on these historical conditions, see the chapter "Los

Pobladores del Valle," by Antonio Viñayo Gonzáles, in San Fructuoso y

su tiempo, 1966, 195ff.; as well as the chapter "La España rural des siglo

VII," by Florentino-Augustín Diez Gonzáles, ibid., 47ff.

FROM CHINA TO EUROPE DURING THE

MIGRATION PERIOD?

The display of water-powered trip-hammers on the Plan

of St. Gall gives added credence to such literary sources

as had been adduced by Bloch, Gille and Carus-Wilson[530]

in favor of the contention that hydraulic trip-hammers were

operated in eleventh- and twelfth-century Europe; as well

as the claim advanced by Uccelli and White[531]

that the fulling

mills of Prato made use of hydraulic trip-hammers from

the beginning of this industry in A.D. 983.[532]

An even

earlier reference (datable 883-904) to molinis vel pilis is to

be found in the Formulae Sangallenses miscellaneae.[533]

Bradford B. Blaine, in his forthcoming book, Water-Power in

Medieval Industry, focuses more intensely than has hitherto been done

on the profoundly significant industrial revolution, discernible by the

beginning of the eleventh century throughout the Alpine forelands,

involving the marriage of the waterwheel and the cam, as witnessed by the

appearance of water-driven hammers used for fulling, crushing hemp,

and forging iron (personal communication). The pilae of the Plan of

St. Gall disclose that this union was achieved considerably earlier (cf.

p. 235, n. 26 and my remarks, pp. 237ff).

Formulae Sangallenses Miscellaneae, Chap. 11, in Mon. Germ. Hist.

Leges, Sec. V, 1886, 385: Dedi itaque ego N. ad cellam sancti ill. villam

eidem loco vicinam . . . id est domibus, pomariis, exitibus et introitibus, viis,

aquis aquarumque decursibus, at clausuris, molinis vel pilis, agris, pratis,

silvis communibus aut propriis pascuisque in omnem partem vergentibus

mancipiisque, iumentis et peccoribus vel cunctis utensilibus. The passage was

brought to my attention by Bradford B. Blaine.

EUROPEAN SOURCES BEFORE MARCO POLO

A literary account of poetic beauty of water-driven

trip-hammers, written decades before Marco Polo's visit

to China (A.D. 1280), is to be found in a remarkable thirteenth-century

description of the waterworks of the monastery

of Clairvaux. There, after telling how the river Aube

had been deflected from its natural course, the writer

traces the water's path as it travels from workshop to

workshop, "launching itself at once upon the wheels of the

mill, and lashed into foam by their motion, it grinds the

meal under the weight of the millstones, and separates the

fine from the coarse by a sieve of fine tissue." Then, after

a brief excursion into the brewery, "where it fills the

boiler and is heated for brewing. . . not hesitating nor

refusing any who requires its aid," it follows the call of the

fullers, at whose workshop, close by the mill, "you may

see it causing to rise and fall alternately the heavy pestles,

that is to say, hammers or wooden foot-shaped blocks—for

that name seems to agree better with the treading-work, as

it were of the fullers—and so relieves them of the heaviest

part of their labor" (sed graves illos, sive pistillos, sive malleos

dicere mavis, vel certe pedes ligneos—nam hoc nomen saltuoso

fullonum negotio magis videtur congruere—alternatim elevans

atque deponens, gravi labore fullones absolvit. . .)[534]

Descriptio Monasterii Clarae-Vallensis, ed. Mabillon, II, 1690

cols. 1306-1309; and 4th ed., II:2, 1839, cols. 2529-33; reprinted in

Migne, Patr. Lat., CLXXXV, 1879, cols. 569-73, and in extract in

Mortet and Deschamps, II, 1929, 27-29. A translation of this text into

French may be found in D'Arbois de Jubainville, 1858, 329-88; into

English in Eales, 1912, 461-67.

TRIP-HAMMERS WITH VERTICAL PESTLES

There existed in the Middle Ages, as already mentioned,

yet another pounding mechanism making use of camming

action that cannot be overlooked in this context. It worked

with vertical pestles rather than with recumbent hammers.

Illustrations of these are found in the Mittelalterliche

Hausbuch of about 1480,[535]

in several manuscripts of

Leonardo da Vinci[536]

and in the manuscript attributed

to an anonymous Hussite engineer of around 1430 (fig.

456). Needham considers these vertical stamping mechanisms

"as characteristically European as the recumbent

tilt-hammer was Chinese."[537]

This may be true, but there

is no historical assurance whatsoever that in Europe the

invention of the former preceded the adoption of the

latter[538]

and any attempt to interpret the pilae of the Plan

of St. Gall, or the pistillos, sive malleos, vel certe pedes

ligneos of the thirteenth-century description of the water-powered

trip hammers of the Abbey of Clairvaux in the

light of this vertically operated pounding mechanism

would be straining the available historical evidence beyond

the limits of propriety. Amongst the vertical medieval

crushing devices listed by Needham, or anyone else

as far as I can see, there is not a single one with pestles

the shape of which could in any manner be compared

with that of a hammer (malleus) or a foot-shaped member

(vel certe pedes ligneos). A hammer, whether struck horizontally

or vertically, hits its object on impact, in a position

which places its longitudinal axis parallel to the surface

that receives its blow. It can accomplish this only with the

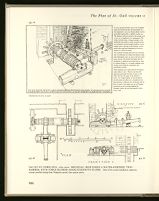

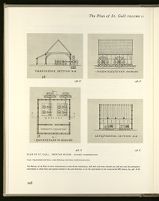

PLAN OF ST. GALL. MORTAR HOUSE. AUTHORS' INTERPRETATION

458.B

458.A

458.D

458.C

PLAN. TRANSVERSE SECTION, LONGITUDINAL SECTION; SOUTH ELEVATION

The Mortars of the Plan are here reconstructed as water-driven mechanisms, with their axle-trees oriented east and west and the presumptive

waterwheels to which these were geared oriented in the same direction, as are the waterwheels of the reconstructed Mill (above, fig. 448. A-E).

PLAN OF ST. GALL. AUTHORS' RECONSTRUCTION

458.E

458.F

WEST ELEVATION, NORTH ELEVATION

If a stream existed on the site and the land gradient permitted the development of waterpower, great efficiency could be achieved by this

alignment of the wheel races. For justification of water-powered mechanisms see above, p. 232, caption to fig. 448. In actual construction, we

believe such details would have been resolved by experienced craftsmen.

its longitudinal axis. In the vertical crushing mechanism,

illustrated by the anonymous Hussite engineer (1472-78),

the Hausbuch Master (ca. 1480) and Leonardo da Vinci

(turn of the fifteenth to the sixteenth century), the pestles

are pointed, i.e., pencil-shaped, and could not by any

stretch of the imagination be interpreted as "hammer-" or

"foot-shaped" instruments. There is no doubt in my mind

that the pilae shown on the Plan of St. Gall must be interpreted

as recumbent hammers. They have the shape of

hammers, and the presence of a drum at the end, which

lies opposite the head of the hammer, as well as their

dimensions, allows for no other interpretation.[539]

For detailed references to Leonardo's drawings of vertical crushing

mechanisms see Needham, op. cit., 395, note d.

It has been generally overlooked in this discussion that the same

anonymous Hussite engineer, who furnishes us with the earliest visual

representation of a vertical pestle stamp provides us also with an illustration

of a grain-crushing mechanism, operating with recumbent

hammers (Munich, National Bibliothek, Ms. lat., fol. 17v; see Beck,

op. cit. 278-80). I am drawing attention to this fact because there seems

to be a tendency, in the literature on this subject, to think that in Europe

the use of the vertical pestle stamp preceded that of mechanisms working

with recumbent hammers, because of the erroneous view that the former

is earlier attested in the visual arts. This would not only be a conclusion

highly questionable in itself, but also one based on mistaken facts. Both

instruments portrayed and described by the Hussite Engineer are hand-operated

and of rather light construction, made for home rather than

industrial use, and therefore not really comparable to the heavy equipment

shown on the Plan of St. Gall or described in the poetic thirteenth-century

account of the waterworks of Clairvaux.

The traditional date of Ms. Lat. 197, "ca. 1430" (Beck, 1899, 280;

Needham, IV:2, 1965, 395; Horn, Journal of Medieval History I, 1975,

244) must be revised. Lynn White informs us that Bert A. Hall, in an

unpublished dissertation "The so-called `Manuscript of the Hussite Wars

Engineer' and its Techological Milieu: A Study and Edition of Codex

Latinus 197, Part 1," University of California, Los Angeles, 1971) showed

conclusively that it is two manuscripts bound together. They are from

the hands of two engineers, neither of whom can be shown to have had

any involvement in the Hussite Wars. Folios 1-28 can be dated to ca.

1472-1485, folios 29-48 to ca. 1485-1496.

It has been generally overlooked in this discussion that the same

anonymous Hussite engineer, who furnishes us with the earliest visual

representation of a vertical pestle stamp provides us also with an illustration

of a grain-crushing mechanism, operating with recumbent

hammers (Munich, National Bibliothek, Ms. lat., fol. 17v; see Beck,

op. cit. 278-80). I am drawing attention to this fact because there seems

to be a tendency, in the literature on this subject, to think that in Europe

the use of the vertical pestle stamp preceded that of mechanisms working

with recumbent hammers, because of the erroneous view that the former

is earlier attested in the visual arts. This would not only be a conclusion

highly questionable in itself, but also one based on mistaken facts. Both

instruments portrayed and described by the Hussite Engineer are hand-operated

and of rather light construction, made for home rather than

industrial use, and therefore not really comparable to the heavy equipment

shown on the Plan of St. Gall or described in the poetic thirteenth-century

account of the waterworks of Clairvaux.

The traditional date of Ms. Lat. 197, "ca. 1430" (Beck, 1899, 280;

Needham, IV:2, 1965, 395; Horn, Journal of Medieval History I, 1975,

244) must be revised. Lynn White informs us that Bert A. Hall, in an

unpublished dissertation "The so-called `Manuscript of the Hussite Wars

Engineer' and its Techological Milieu: A Study and Edition of Codex

Latinus 197, Part 1," University of California, Los Angeles, 1971) showed

conclusively that it is two manuscripts bound together. They are from

the hands of two engineers, neither of whom can be shown to have had

any involvement in the Hussite Wars. Folios 1-28 can be dated to ca.

1472-1485, folios 29-48 to ca. 1485-1496.

RECONSTRUCTION OF PILAE ON THE

PLAN OF ST. GALL

Using as a model the trip-hammers of the iron forge of

Spechtshart's Flores Musicae (fig. 455), the trip-hammer of

the monastic smithy of Compludo (fig. 457), and the modern

example described by Meringer (fig. 453), we have reconstructed

the mortars of the Plan of St. Gall as water-driven

crushing hammers whose movement is controlled by the

cogs of a cylindrical drum mounted directly upon the axis

of a waterwheel (fig. 458).

DIETARY IMPORTANCE OF CRUSHED GRAIN IN

WESTERN EUROPE

The amount of crushed grain used daily in a medieval

monastery must have been considerable. A mixture of

barley and oats, made into a kind of porridge or "pap" by

the crushing action of the mortar was a chief item in the

diet of the people of Western Europe prior to the introduction

of the potato. The German word for this dish is mus,

and in the monastery of St. Gall the use of this term, as

459.A PLAN OF ST. GALL. DRYING KILN. AUTHORS' RECONSTRUCTION [1:192]

The shelter for the Drying Kiln is identical with those for the Mills and

Mortars of the Plan. This house could have been the simplest kind of structure,

perhaps even open-sided. Although the Drying Kiln would not develop

temperature so high as those needed for baking, some fire hazard would have

existed in a closed building; the Plan does not show either smoke exit or stack

port for this facility. We reiterate that these service structures of the Plan are

highly abstract; their purpose and siting were of foremost importance to the

Plan's makers; their constructional details, secondary.

Kero renders the Latin word cibus, i.e., "food," with the

German word mus, and caenare, i.e., "to take one's supper,"

with the term abendmussen, i.e., "to sup on pap."

Crushed grain was also one of the primary ingredients in

the making of beer.[541]

| The Plan of St. Gall | ||