The Plan of St. Gall a study of the architecture & economy of & life in a paradigmatic Carolingian monastery |

| II. |

| V. |

| V. 1. |

| V. 2. |

| V. 3. |

| V. 4. |

| V. 5. |

| V. 6. |

| V. 7. |

| V. 8. |

| V. 9. |

| V. 10. |

| V. 11. |

| V. 12. |

| V. 13. |

| V. 14. |

| V. 15. | V. 15 |

| V.15.1. |

| V.15.2. |

| V.15.3. |

| V.15.4. |

| V. 16. |

| V. 17. |

| V. 18. |

| VI. |

| The Plan of St. Gall | ||

V. 15

FACILITIES FOR GRINDING,

CRUSHING, & PARCHING OF GRAIN

V.15.1

THREE IDENTICAL BUILDINGS FOR

DIFFERENT FUNCTIONS

Along the southern edge of the monastery, directly behind

the Bake and Brew House for the Monks, are ranged three

rectangular structures which house the apparatus needed

in the three main phases of preparation of bread and beer:

the grinding, crushing, and parching of the grain (fig. 438).

Only one of these, the Drying Kiln, is identified by a

descriptive legend: "the place in which the grain is

parched" (locus ad torrendas annonas). The purposes of the

other two may be inferred from their equipment, which

consists of two large "mortars" (pilae) in one, and two

"millstones" (molae) in the other. The buildings are identical

in shape and may be assumed to be of identical construction.

They measure 35 feet by 35 feet and are internally

subdivided into a principal work space 25 by 35 feet, which

contains the basic machinery, and a lean-to 10 feet wide,

serving as the dormitory for workmen (eorundem famulorum

cubilia). As in the more elaborate structures of the Plan,

the servants' quarters are not accessible from the outside,

but from the interior only. We assume that in their

exterior appearance these buildings looked much like the

mill shown in the background of the painting Seated

Madonna by Gerhard Memling (fig. 439A), now in the

Uffizi at Florence.[471]

This painting also gives us an idea

about the device used to provide power in the operation

of mills and mortars—a subject that is controversial and

requires further explanation.

Friedländer, VI, 1934, Pl. 35. The motif was copied by Lorenzo di

Credi in a painting of the Madonna and Child with Angel, which is now

in the Getty Museum at Malibu Beach, California. That Lorenzo di

Credi copied it from Memling was brought to my attention by Juergen

Schulz. Cf. Degenhard, 1932, 140.

V.15.2

THE MILL

MAN-, ANIMAL-, WATER-POWERED?

THE ROMAN TRADITION

Ferdinand Keller referred to the molae of St. Gall as

"hand mills."[472]

Albert Lenoir expressed the same view:

"The place they occupy in the room, as well as the absence

of any sort of motor mechanism in the vicinity, permits no

doubt that these mills were operated by the hand of man."

He felt convinced that they were similar to a type of mill

common among the ancients, which was set in motion by

driving the upper stone on a center spindle with a wooden

bar (fig. 440).[473]

For commercial purposes the Romans used a

larger variation of this type of mill; its size required

the strength of a donkey or horse to turn it, or lacking

such beasts of burden, it was turned by slaves (figs. 441442).

In the first century B.C., these devices found a

powerful rival in the water mill.[474]

Among the Roman water

mills two basic types can be distinguished: the vertical

mill (fig. 443A), in which the millstone is turned by means

of a water paddle attached to the lower end of a vertical

spindle; and the horizontal or "Vitruvian" mill, the type

in which a vertical water wheel is mounted on a horizontal

axis, from which its rotation is transmitted to the millstone

spindle by a pair of cogwheels (fig. 443B). The vertical mill

is typologically the more primitive form, and therefore

considered by some to be the earlier one.[475]

The "horizontal"

water mill was probably a Roman invention, and

judging from Vitruvius' description (23-25 B.C.), it was

still a relatively recent phenomenon at the time of his

writing. The earliest water mills of the city of Rome

apparently were installed in the Tiber "a little before

Augustus,"[476]

but for the first three centuries of the Empire

man-powered or animal-driven mills remained in the

majority.[477]

It was only from the beginning of the fourth

century onward that the water mill began to supersede the

earlier forms. The earliest pictorial representation of the

Vitruvian water mill is to be found on a fifth-century

439.A GERHARD MEMLING. SEATED MADONNA

FLORENCE, UFFIZI GALLERY. DETAIL

[Courtesy of the Gabinetto della Soprintendenza alle Gallerie]

The painting shows in the background a Northern waterwheel in a form that the

artist perceived it; the work, probably about mid-15th century, cannot be dated

with precision.

mill dating from the time of Leo I (457-474) has recently

been excavated in the Agora of Athens.[479] As early as A.D.

370 water-driven corn mills and saws for cutting marble

were seen by Ausonius on the Ruwer, one of the tributaries

of the Moselle River.[480] An intensely industrial application

of water power for the grinding of grain was a

Roman flour factory with sixteen wheels, erected 308-316

on a mountain slope at Barbegal near Arles (fig. 444). It

worked with two sets of eight overshot wheels, fed by two

channels of water from the aqueduct of Les Beaux, and

could produce in a ten-hour day, with all wheels in operation,

a total of twenty-eight tons of flour, sufficient to feed

a population of 80,000—which fact suggests that it supplied

the entire army of the province of Narbonne (besides

meeting the local demands of Arles, which had a population

of 30,000). There is archaeological evidence for the

existence of a similar flour mill at Prety (Pistriacum), near

Tournus, Burgundy, which ground the grain of the Saone

439.B GERHARD MEMLING. MADONNA AND CHILD

LONDON, NATIONAL GALLERY. DETAIL

[Courtesy of the National Gallery, London. Photo no. 61275]

The waterwheel in the London version of the painting is substantially of the

the same design, and shows with greater detail some of its construction. This

painting dates to about 1468.

supply for the army of northern Gaul.[481] These two facilities

were unusual and owed their existence, unquestionably, to

pressing military demands, but their existence nevertheless

denotes a general trend.

The historical motivations for this mounting interest of

the fourth-century Romans in water as a source of power

for grinding grain are still somewhat mysterious. One cause

was, without doubt, the increasing shortage of slave labor

in the later days of the Roman empire; another one, the

new attitude toward labor associated with the Christian

concept of caritas, resulting in the view that the forces of

nature should be captured and trained to ease the life of

man; still another cause, perhaps, was the fact that the

center of cultural gravitation had shifted from the Mediterranean

basin, where most rivers carry widely varying

quantities of water in different seasons, to a northern area

that abounded with mountain streams fed by a constant

flow of water. Finally, but not least to be contended with:

440.A, B, C, D HAND OPERATED ROMAN MILLS

Stationary or portable mechanisms like these shown above were used in every

Greek and Roman household and were diffused throughout Europe by Greek and

Roman armies. In Roman military camps, where soldiers ground their own corn,

such handmills were a common sight. One mill was provided for every ten men;

each soldier was prepared to carry his own thirty-day flour supply (Forbes, 1956,

109; Moritz, 1958, 116; Horn, 1975, 223, and 231, fig. 7).

The upper stone, in examples A, B, C, D,

weigh, respectively, about 130, 55, 30 and

45 pounds. Quern A, with two handles, could

be operated by two persons. Quern D, a great

advance in the art of milling, provided for

adjustment of the upper stone by an under-table

device that controlled clearance between

stones at their outer rims, thereby regulating

the fineness of the milled particles. Advances

in the arts of military machines were paralleled

by invention in the agrarian arts.

were not slow in putting into the service of their growing

manorial economy technological devices that offered new

prospects of exploitation to the landlords who had the

right and means of building and of operating these mills.[482]

ROMAN MILL IN POMPEII

441.A

441.B

[After Mau, 1908, 408, fig. 237]

The mill of Pompeii operates on the same principle as the table pepper mill. Its

lower fixed stone (meta) is raised on a plinth that also forms a basin to catch freshly

ground flour. The mill is charged with grain at the top; kernels fall into the space

between the two stones (which can be enlarged or decreased by adjusting the spindle

of the moving stone, the catillus, on its overarm) and are ground at the lower edge of

the catillus flange where it touches the meta.

441.C ROMAN DONKEY MILLS

POMPEII. REMAINS OF A ROMAN BAKERY WITH

FOUR DONKEY MILLS AND A BAKING OVEN

[after Forbes, 1956, 110, fig. 77]

Donkey mills are known to have been used in Greece from about 300 B.C. They

could be set up anywhere on land, and for that reason became the favorite Roman

flour mill. The turning circles the animals were forced to follow in this and other

mills of the type were brutally narrow.

442. ROME, MUSEO CHIARAMONTI. FRAGMENT OF A SARCOPHAGUS (2nd cent. B.C.)

HORSE HARNESSED TO A DONKEY MILL

[By courtesy of the Archivio Fotografico delle Gallerie dei Musei Vaticani]

The relief shows the hourglass shaped mill being worked by a horse harnessed to a trace that fits into the rotating upper stone of the mill (cf.

fig. 441. A). The question of the relative distribution of water- and animal-powered mills in medieval Europe, and their differing functions,

requires a new systematic study. In an inquiry into conditions prevalent in certain Carolingian territories west of the Rhine, Weber reaches the

same conclusions that Bennett and Elton came to more generally:

"Wenn man die urkundlich nachweisbaren Standorte berücksichtigt, weiss man auch, dass es sich bei unseren Beispielen nur um Wassermühlen

gehandelt haben kann. Die von Tieren getriebene Mühle bleibt fortab die Ausnahme. Sie wird meist nur für Notfälle eingerichtet, z.B. auf

Burgen und ummauerten Städten für die Zeiten langdauernder Belagerungen." (F. W. Weber, "Die ersten urkundlich nachweisbaren

Wassermühlen westlich des Rheins," Pfälzer Heimat, vol. 3/4, Dec. 1972, 101-103. The journal is not easily available outside Germany.)

ROMAN WATER MILLS

443.A Horizontal water wheel at the end

of a vertical shaft fixed to the

upper millstone.

443.B Vertical waterwheel, with power

transmitted to the upper millstone

by means of gears.

[redrawn by C. B. Lund, after Forbes 1956, 595, fig. 540]

The earliest water mill of which we have any record is one to which the Greek

historian Strabo refers as having been built by the Pontic king, Mithradates VI

Eupator, in his palace at Cabeira (some distance inland from the southern shore

of the Black Sea), which was completed in 63 B.C. (For sources and a

suggestion that this may indicate an Asiatic origin, as in the case of the water-powered

triphammer, see Horn, 1975, pp. 226-27 and below, pp. 245f.)

The origins and the early history of the water mill have been dealt

with in a comprehensive work by Bennet and Elton, 1898-1904, competently

reviewed and amended in a recent article by Curwen, 1944, and

brilliantly rediscussed in a masterful book by L.A. Moritz, 1958. There

is also a basic study by Bloch, 1935, and an historical review by Forbes,

1957. Also see Horn, Journal of Medieval History, I, 1975 219-57.

Others question this view of Moritz, 1958, 131ff. With the exception

of a narrow stretch of land in southwestern France, this type is not well

attested for medieval Germany, France and England. Cf. Curwen's

distribution map, which is based on its modern survival forms (Curwen,

1944, 145, fig. 6).

To the hand-, donkey-, and water-driven mill, we will have to add

as a fourth category the mola divino numine rotata, if the author of the

Life of St. Winnoc may be trusted in his touching account of an event

that occurred late in the seventh century. In order to demonstrate his

humble spirit, Winnoc, the head of a small monastic cell in Worumholt,

Flanders (today: Wormhoudt, Dept. du Nord, arr. Dunkerque), toward

the close of his life decided "that he wished to rotate the mill with his

own sacred hands [molam suis sacris rotare manibus], and thus in grinding

grain into flour, served in daily labor the brothers who lived in this

place as well as Christ's paupers whom he often received there with

great benevolence." The brothers failed to understand how the feeble

and aged Abbot could produce the amount of flour that left his mill

daily, and spying upon him, discovered that the mill "was operated by

the will of God" [divino numine rotatum] rather than by the Abbot's

own hands. The latter simply stood to the side of the stones, his arms

raised in the gesture of prayer (Vita Andomari, Bertini, Winnoci, chap.

25, in Mon. Germ. Hist., V, 1910. 771-72).

Parsons, 1936. The Athenian mill was an overshot; the Vitruvian mill

and the mill on the mosaic of the Palace at Constantinople were undershot.

"As he the river Ruwer turns his millstones in furious revolutions,

and drives the shrieking saws through smooth blocks of marble,"

Ausonius, Mosella, lines 359-64. See Ausonius, ed. Evelyn-White, 1919,

253. But take note that Lynn White, 1962, 82ff, expresses some doubt

concerning the reliability of the manuscript tradition of the Mosella

poem.

For a succinct discussion of the converging historical factors that

might have contributed to the increasing use of water power from the

fourth century onward see Forbes, 1957, 601ff, on whom I am heavily

leaning with this summary. On the new Christian attitude toward labor

see Geoghegan, 1945, 93ff, and Benz, 1964, 241-63.

THE MONASTERY A PRIMARY AGENT

IN THE HARNESSING OF WATER POWER AND IN

DIFFUSING ITS USE

The medieval monastery, a leader in all other aspects of 444.B CONJECTURAL RECONSTRUCTION [after Forbes 1956, 599, fig. 547] 444.A PLAN [after Forbes 1956, 598, fig. 546; redrawn by C. B. Lund] ROMAN INDUSTRIAL WATER MILL, 308-316 A.D. The mill was serviced by an aqueduct. It worked with two sets of eight overshot

rural economy, became one of the primary agents in the

dissemination of water power for the grinding of grain as

well as for many other uses. The earliest transalpine water

mill put to monastic use is recorded by Gregory of Tours

at the time of the Visigoth ruler Alaric (484-507).[483]

This

account is of particular interest, since it tells us how, during

and for a short time after the construction of the monastery

of Loches (Indres-et-Loire) by Abbot Ursus, "the brothers

ground the wheat required for their sustenance by turning

the millstones by hand" (molam manu vertentes). Ursus

decided to supplant their labor by constructing a mill at

the banks of the river Endria: "Setting stakes across the

river and heaping a great pile of large stones, he built

sluices, gathered the water in a channel, and by its impetus

thus drove the wheel of the work into swiftly spinning

BARBEGAL (ARLES), FRANCE

wheels, fed by two channels of water, and could produce in a ten-hour day, with

all wheels in operation, enough flour to feed the nearby city of Arles and the

entire army of the province of Narbonne.

vertere fecit). Another water mill is mentioned by the same

Gregory of Tours in his description of the city of Dijon.[484]

More evidence (so far overlooked) attesting the rapid

spread of use of water mills in Merovingian Europe may

be found in the Lives of Father Romanus (fifth century),

of St. Remy (ca. 437-533), and of Athala, Abbot of Bobbio

(615-627).[485]

The availability of water for the operation of a

445. HERRADE DE LANDSBERG. HORTUS DELICIARUM (1195), fol. 112A

(formerly) STRASSBOURG, BIBLIOTHÈQUE PUBLIQUE

[after Straub and Keller, 1901, pl. xxx]

Two women attend a water-powered mill. This illustration

is after a postmedieval copy of a manuscript that was

destroyed during the Franco-German war.

situating a monastery which Count Wibertus and Countess

Ada, during the reign of King Pippin, erected for their

daughter St. Hiltrud (d. ca. 790) at Liessies.[486] Two water

mills on the Leto River were given to the monastery of

Aniane by Charlemagne in a donation charter dated Aachen,

June 799;[487] another one in the vicinity of Dover is mentioned

in a charter of King Ethelbert, dated 762.[488] The

context of the chapter in which Abbot Adalhard in 822

defines the duties and privileges of the millers employed

by the Abbey of Corbie and its various dependencies leaves

no doubt that he is referring to water-powered mills, since

he stipulates that the millers be furnished, inter alia, with

everything that is required for the maintenance and repair

of their sluices (sclusa).[489] The Abbey of St.-Riquier in 798

had a water-driven mill which received its power from a

small stream called Scarduo running through the middle

of the monastery.[490] From the ninth century onward references

to water mills are made with increasing frequency.

An interesting incident in connection with the establishment

of water mills is the account of the failure of Abbot

Habertus of Laubach (d. A.D. 835) to cut an aqueduct to

channel water to the mills through the rugged slopes of the

mountain which surrounded his monastery.[491] In the centuries

that follow, references to water mills become legion.

The Domesday Book (ca. 1080) lists 5,624 of them.[492] From

the twelfth century on they are frequently depicted in

illuminated manuscripts. In the precision of their detail,

some of these representations compare favorably with

modern engineering drawings; (cf. fig. 445).[493]

Gregorii Episcopi Turonensis Liber Vitae Patrum, chap. xviii, in

Mon. Germ. Hist., Scriptores Rerum Merovingicarum, I, 1881, 734-35.

Cf. Bloch, 1935, 545.

Gregorii Episcopi Turonensis Historia Francorum, Book III, chap.

19, in Mon. Germ. Hist., op. cit., 128; and The History of the Franks by

Gregory of Tours, ed. Dalton, II, 1927, 103: "Before the gate it turns

mill-wheels with wondrous speed."

For the life of Father Romanus see: Vita Patrum Iurensium Romani,

Lupicini, Eugendi, Book I, chap. 18, in Mon. Germ. Hist., op. cit., III,

1896, 141; for the life of St. Remy see: Vita Remigii Episcopi Remensis

Auctore Hincmaro, ibid., 306-7; for the life of Abbot Athala see: Vitae

Columbani abbatis discipulorumque eius libro duo auctore Iona, Book II.

(Vita Atalae), chap. 2, in Mon. Germ. Hist., op. cit., IV, 1902, 114-15.

Vita S. Hiltrudis Virginis in Coenobio Lesciensi, chap. 2, in Schlosser,

1896, 226-27, No. 705.

"Primo enim acqua rivuli Scarduonis medium praeterfluens claustrum,

ibidem farinarium in usus fratrum volvebat." (Schlosser, 1896, 263, No.

792).

Folcuini Gesta Abbatis Lobiensis, chap. 12, ibid., 67-68, No. 237:

"temptavit et idem abbas aquaeductum a foreste ducere, ardua montium

sulcans, sed perficere non potuit opus praeposterum et sero inchoatum."

Fig. 445 is fol. 112a in the Hortus Deliciarum of Herrade de Landsberg

(ed. Straub and Keller, 1901, pl. XXX). Herrade became Abbess

of the monastery of Hohenburg in 1167 and died in 1195. The earliest

pictorial representation of a medieval water mill (according to Bennet

and Elton, II, 73) is to be found in a French manuscript of the twelfth

century, British Museum, London, Harley Ms. 334, fol. 71v. It is

undershot, as are most of the medieval mills depicted in manuscripts.

That overshot wheels were in use, however, as early as the thirteenth

century, is demonstrated by a water mill represented in the Sachsenspiegel;

cf. von Künssberg, 1934, fol. 65 (the manuscript dates from

1221-24).

EVIDENCE FOR A WATER-POWERED MILL

In the light of this abundant and clear evidence, Keller's

and Lenoir's opinion that the mills of St. Gall were hand-operated

mechanisms seems quite open to debate. What

Keller had in mind, I should think, was the kind of hand

mill that is depicted in a German manuscript of the fourteenth

century (fig. 446), reproduced by Bennet and

446. MEDIEVAL HAND MILL

The drawing, from a German 14th-cent. manuscript, shows a mill

derivative of the hand-operated Roman mill (fig. 440. A, B) that

survived the advent of the watermill.

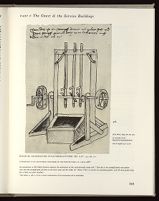

447. HAUSBUCH MASTER. MILLING APPARATUS

CA. 1480

[after Bossert and Stork, 1912, pl. 46]

Although the drawing is rendered in the clumsy perspective of a

Middle Rhenish master of the pre-Dürer period, it portrays the

milling mechanism with great factual accuracy. The pen and ink

drawing appears in a manuscript written and illustrated by an

official who in 15th-century Germany was called "Büchsenmeister"

—master of firearms. Of relatively high social standing, such a

personage would today hold a position comparable with civil or

military engineer. (The manuscript is the property of Fürst

Waldburg-Wolfegg-Waldsee.)

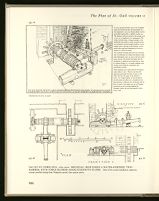

448.B, C PLAN OF ST. GALL. MILL

AUTHORS' INTERPRETATION. GROUND PLAN

Waterpower for the Mill and Mortar of the Plan of St. Gall is a viable proposal; we have therefore reconstructed the mechanisms as water driven, for these reasons:

As regards the millstones, their size, at a literal diameter of 7½ feet, would tend to eliminate the possibility of hand operation. Their depiction on the Plan lacks any

indication of drive systems, but that lack is consistent with other such omissions where practicalities, to be left to a master craftsman to execute, have been eliminated in

favor of clarity of scale and function.

The alignment of mills and mortar on the southern edge of the Plan site would facilitate use of water power assuming that a stream existed on the site and could be

channeled down a gradient sufficient to provide it (cf. I, 68-69 and fig. 53). Abundant documentary evidence shows that from the end of the 5th century onward and

with increasing frequency in succeeding centuries, monastic mills of transalpine Europe were water powered; finally, references to animal-driven mills in these some

sources are almost entirely lacking (see above, p. 228, fig. 442 caption).

We have already discussed the question of why the Romans, although they had it, made scant use of the water mill; whereas the young barbarian nations of the north

adopted and diffused it with enthusiasm. To reasons already set forth we suggest here, as a factor so far overlooked, that the strongest impetus for the phenomenal spread

of waterpower in the early Middle Ages came not from the secular world but from the ascendancy of Benedictine monasticism.

The records of many abbots show that extensive monastic estates included mills located far outside the immediate vicinity of the monastery; Gozbert himself doubtless

would have controlled several beyond the two proposed by the Plan for the monastery. Adalhard records that Corbie's bakeries had to produce 450 one-pound loaves

each day, for which the monastery drew on an annual volume of 5,475 modii of grain from 15 mills, each of six millstones, all of which had to be maintained in good

working order (see III, 106-107). And the abbey of St.-Germain-des-Prés had several times again that number of mills (see Horn, 1975, 248ff, for details and sources.)

Building and operating such facilities required impressive capital investment dependent on ownership of great acreage and an unparalleled degree of managerial

competence. The monastic school-trained leaders of the period brought to the vast monastic holdings the ingenuity and spirit of radical innovation that necessity alone

would have made welcome. In addition, the monastries and their high officials had the pressing moral committment to free the monks from long hours of arduous

physical labor, in order to further the Opus Dei. By contrast the secular world, lacking intellectual advantages, integrated physical resources, administrative unity, and

religious incentives, lagged behing the great monastries in technical innovation; as in most labor-intensive societies, medieval secular institutions tended toward

conservatism.

Gregory of Tours leaves as an anecdote about Abbot Ursus that constitutes the first documentary evidence of a monastic mill. After relating that "on account of this

[water mill] the work that formerly had to be done by many monks could now be accomplished by a single brother," Gregory repeats a dialogue between Ursus and

Sichlerius, a Visigoth and nobleman whose land bordered the abbey's, and who had seen first hand the installation of the new mill and its sluices:

"Covetous to acquire the mill, he told the abbot, `Give me this mill, to become my property, and I shall give you, in return, whatever you ask for,' Replied the Abbot:

`It was only with the greatest of pain, on account of our poverty, that we were able to install this mill; and now we cannot give it to you lest our brethren die of

hunger.' Sichlerius retorted: `If you wish to give it to me by your own free will, I shall be grateful. Otherwise I will take it by force, or build another mill, for which I

shall divert the water from your sluice; and in this way it will no longer be able to turn your wheel.' The abbot replied, `You will not do what God shall not permit you

to do, you will not take it at all!' Sichlerius, in ire, did what he had threatened to do, but because of divine intervention, the water failed to turn the wheels of his

mill." Thus the intransigent noble was defeated.

The story, embodying all the social dichotomies between secular and religious spheres, is symptomatic and may have remained so for the most of the Middle Ages.

Ingenuity and initiative, in addition to divine justice, were clearly on the side of the abbot.

PLAN OF ST. GALL. MILL

448.D LONGITUDINAL SECTION

448.E TRANSVERSE SECTION

AUTHORS' INTERPRETATION

type could never have produced the volume of flour needed

in a settlement the size of that represented on the Plan of

St. Gall. Hand-operated mills, because they were subject

to the limitations of manual operation, were bound to be

small. Yet the millstones of the Plan are not only large,

they seem colossal. They are drawn at a diameter of 7½ feet.

Even if the representation is not literal,[495] such weight and

volume could not possibly have been set in motion by manual

operation. There are other factors suggesting water power.

The drafter of the Plan, as we have seen, did not consider it

part of his task to include a delineation of the monastery's

water system, but he was not oblivious to the fact that

buildings requiring water power would have to be located

in places to which water could easily be conducted. This is

clearly indicated by the way he carefully aligned all the

buildings and activities requiring water along the edge of

449.C LUTTRELL PSALTER (1340). LONDON, BRITISH MUSEUM. ADD. MS. 42130, FOL. 207

BY COURTESY OF THE TRUSTEES OF THE BRITISH MUSEUM

A cook tends his kettles and his assistant wields choppers; at the right a third man macerates some substance with a long pestle in a large

container. It is not clear whether he is pounding meat (as Millar, 1932, 49, thought), crushing grain, or churning butter.

it could have been channeled to serve all of them

efficiently.[496]

Bennet and Elton, I, 1898, 163. For modern parallels of this type of

hand mill, see Meringer, 1909, 166-67.

This dimension should not be taken too literally. The maker of the

Plan, as has been previously shown, defined all pieces of equipment and

furniture as multiples of the 2½-foot module. When a piece of equipment

did not fit into this graduation, he rounded off its dimensions to

the next higher modular value, never to the lower one. If the diameter of

the millstone is rendered as three 2½-foot modules (7½ feet), this means

that it was larger than two 2½-foot modules (5 feet), but not necessarily

as large as three 2½-foot modules (7½ feet). It could have been at any

reasonable point between 5 feet and 7½ feet. (Cf. our discussion of the

dimensions of the beds in the Monk's Dormitory I, 89-90, as well

as the general analysis of the scale and construction method used in

designing the Plan, I, 77ff).

I have not been able to find any reliable information on the size of

medieval millstones. The average diameter may not have been more

than 4 feet. But monastic millstones, because of the immense volume

of bread to be baked per day, (in Corbie 420 one-pound loaves daily!

cf. III, p. 106) they are likely to have been considerably larger. In the

summer of 1969 while traveling in Yugoslavia, I saw a millstone 6 feet

in diameter, unfortunately in a place the name of which I have forgotten,

but later on, on the same trip, in the medieval granary of the Abbey of

Le Thoronet in Provence, I came across a millstone with a diameter of

5 feet, 5 inches (it is visible in the interior view of that building, reproduced

on p. 88 of Père M. A. Dimier's L'Art Cistercien, published in

1962).

With regard to the hydrographical patterns of the site see my

remarks on the waterways of the Plan, I, 68-70. The general problem

of the application of water-power to industry during the Middle Ages

has been dealt with by Prof. Bradford B. Blaine of Scripps College, in a

doctoral thesis submitted at the University of California at Los Angeles in

1966, and will form the subject of a forthcoming book by Prof. Blaine,

entitled Water-Power in Medieval Industry.

RECONSTRUCTION OF MILLING APPARATUS

The reconstruction of the milling apparatus poses no

major problem, since both Herrade de Landsberg (1195)[497]

and the Hausbuch Master (ca. 1480)[498]

have furnished us

with very detailed drawings of water-driven milling mechanisms

(figs. 445 and 447). Herrade's mill is undershot. A

large waterwheel transmits its rotation through an axle to

a smaller wheel, the cogs of which are geared into a vertical

drum. The vertical power of the driving wheel is thus converted

into the horizontal motion of the millstone. A hopper

feeds the grain from overhead into a hole in the center of

the upper stone, the so-called "runner". This system is

essentially the same as that of the so-called Vitruvian mill,

except for a difference in the speed of transmitting power.

The Vitruvian mill is relatively small and moves faster

than the wheel that turns the millstone. In the medieval

mill, with its larger waterwheel, the transmission is from

slower to faster.[499]

In our reconstruction of the Mill of the

Plan (fig. 448A-E) we have adopted the latter system.

The Mill of the Plan would have taken care only of those

milling operations which were performed within the monastic

enclosure. On its outlying estates a monastery usually

operated a great number of additional mills. According to

Guérard's calculations, at the time of Abbot Irminon (ca.

800-826) the Abbey of St.-Germain des Prés managed as

many as eighty-four mills on its outlying estates.[500]

The

HAND-OPERATED MORTARS AND PESTLES

OF OAK

449.A.1

449.A.2

[after Keller, 1860, 45 and 50]

BELTIS, LAKE WALLENSTADT, SWITZERLAND

Devices of this kind, used for crushing cereal grains, were in the Middle Ages

employed in every household; porridge made from these grains was one of the

principal items in the common man's diet.

judge from the Administrative Directives of Adalhard of

Corbie, differed from that of the other monastic tenants in

that they were exempt from the manual labor to which the

other tenants were held, such as "plowing, sowing, harvesting

grain or hay, making malt or hops, delivering wood

or anything else in the service of the lord" (ad opus

dominicum).[501] Adalhard stipulates that each miller was to

be provided with a pair of oxen and other things necessary

for the sustenance of himself and his entire family, so that

he could raise pigs, geese, and chickens, and set up his

mill, and might obtain or manufacture all such materials

as he needed in order to improve his mill, repair his sluice,

transport his millstone, and everything else that he might

need to own or manufacture.[502]

449.B LE THORONET, VAR, FRANCE

MORTAR AND PESTLE

Hand mortars of this kind continued in use in the Middle Ages along with

water-powered trip hammers (figs. 454, 457), and were important in seasons

when streams were too low to drive trip hammers.

450. MODERN TRIP-HAMMER

[redrawn after Meringer, 1906, 16, fig. 26]

Trip-hammers of this type are used even today in areas stretching from Central

Europe throughout the whole of Asia, as far as India, China, and Japan. The

hammer shown is of the foot operated type.

Consuetudines Corbeienses, chap. 12, ed. Semmler, in Corp. Cons

Mon., I, 1963, 379, and translation, III, 107.

V.15.3

THE MORTARS

MAN- OR WATER-POWERED? CONFLICTING VIEWS

The crushing devices designated by the term pilae, i.e.,

"pestles," in the house lying west of the Mill (fig. 438),

raise the same problems posed by the milling apparatus.

Were they operated by hand or water? Keller, in this case

too, took the first position. He drew attention to two old

hand-operated mortars which he discovered in the remote

village of Beltis on the lake of Wallenstadt in Switzerland

(fig. 449 A.1, A.2).[503]

One was three feet high, cut out of a

solid trunk of oak, with the interior hollowed out conically.

The pestle, likewise, was made of a single piece of oak,

except for its handle, and was studded with nails at its

base. This, Keller thought, must have been the contrivance

that the drafter of the Plan of St. Gall had in mind when

he drew his peculiar L- or key-shaped pilae (fig. 438).

451. HOKUSAI. JAPANESE TRIP-HAMMER (19th cent.)

[after Singer, Holmgard, Hall, II, 1956, 107, fig. 71]

If his expression of grim determination is an indication, the man acting as

counterweight to the hammer could scarcely have worked harder using a mortar

and pestle for his task.

That instruments of the Beltis type were used during the

Middle Ages is beyond question, and easy proof of this

may be found inter alia in a delightful marginal drawing

of the Luttrell Psalter (fig. 449C), which shows a bearded

cook pounding a huge mortar with a pestle almost twice

his own height.[504]

The mortar, apparently made of iron or

bronze, reaches to slightly above the knee of the pounding

cook, and by that criterion should have been meant to have

a height and width of roughly two feet. The largest implement

of that type I have ever examined is a mortar carved

of a single block of stone, that stands now in the medieval

granary of the Abbey of Le Thoronet in Provence, only a

few yards away from the millstone discussed in an earlier

part of this chapter. This mortar (fig. 449B) has a round

base, 2 feet in diameter, is 3½ feet high, and 4 feet wide at

the top. Its pounding cavity tapers from the rectangular

opening at the top to a conical form at the bottom. The

pestle—which does not look to me to be the original—is

a roughly hewn trunk of a young tree, about 9 inches thick

me that it could be worked with some effort by a single

man, and with ease by two men lifting it in conjunction.

Yet I would be inclined to think that in the Middle Ages

mortars and pestles of this order of magnitude were water

driven, rather than hand-operated mechanisms. This was

also the view of Rudolf Meringer who has made a special

study of this type of instrument. In an article on the implements

of the pinsere series and their names, published in

1909, Meringer[505]

drew attention to the fact that the pilae

of the Plan of St. Gall (fig. 438) were not only considerably

larger than those with which they had been compared by

Keller (fig. 449A) but also of vastly different shape. He

claimed that, rather, they bore striking resemblance to a

type of crushing device which in German is called Anke,

and illustrated his views by a startling juxtaposition of the

pilae of St. Gall and a drawing of a modern water-driven

iron hammer (fig. 453).[506]

The earliest pictorial representation

of a water-driven recumbent western tilt-hammer

appears to be a woodcut in Spechthart's Flores Musicae,

published in 1488 (fig. 455).[507]

In an earlier period this contrivance

was operated by hand or foot, as it was still in very

recent times in Galicia (fig. 450), Poland, China, and

Japan in very much the manner in which this is depicted

in a whimsical drawing by the Japanese painter Hokusai

(fig. 451). Man-powered tilt-hammers of this type, as was

subsequently shown, were used in China in remote periods,

and their design and mode of operation is well attested by

two small models in green glazed pottery from the Han

period (206 B.C. to A.D. 220) which are now in the Nelson

Art Gallery (fig. 452A-C), Kansas City, as well as a Han

moulded brick found at P'en-shan Hsien, in the Szechuan

Provincial Museum, Chengtu (fig. 452D).[508]

Meringer

was convinced that the pilae of the Plan of St. Gall

did not belong to the foot-operated type, but that they were

water driven, and he attempted a reconstruction (fig. 454),

in which the pestle beams were alternately lifted and

released for fall by the cogs of a cylindrical drum mounted

directly upon the axle of a water wheel, as in the modern

iron hammer (fig. 453). Hydraulic trip-hammers of this

or a similar design are attested for China through unequivocal

literary descriptions as early as the reign of Emperor

Wang Mang (A.D. 9-23) and through less reliable sources

perhaps even as early as the third century B.C.[509]

Meringer

could not prove that the camming action employed in this

device was known in Carolingian times,[510]

and his interpretation

of the pilae of St. Gall as hydraulic cam-operated

pounding mechanisms did not come to the attention of

Marc Bloch who, in his classical and widely read study on

the advent and spread of the water mill, referred to the

pilae of St. Gall as "a crushing instrument which, on the

plan, was certainly not shown as being water driven;"[511]

a view which was reiterated in 1954 by Bertrand Gille,[512]

and subsequently adopted, although perhaps not with the

same degree of conviction, by Lynn White in 1962.[513]

Finally, in 1965, it looked as though Meringer's interpretation

had received a final blow, when Joseph Needham,

in his monumental Science and Civilization in China, after

a thorough account of the Chinese history of the hydraulic

trip-hammer[514]

advanced the theory that this mechanism

was introduced in Europe "about the time of Marco Polo,"

in connection with the fulling trade when much other

Chinese textile machinery appears to have made its way to

Europe. Needham proclaimed that all water powered European

stamp mills prior to that period were machines in

which pestle beams moved in vertical action in the manner

illustrated by a drawing made by an anonymous Hussite

engineer around 1430 (fig. 456).[515]

Meringer, 1909, 24ff a study that was brought to my attention by

Lynn White years ago, when I first concerned myself with this problem.

I am greatly obliged to Lynn White for having subsequently kept me

apprised of other publications bearing on this subject.

Meringer had, in fact, already established this comparison two

years earlier; see Meringer, 1907, 285, figs. 8 and 9.

On water-powered Chinese trip-hammers see Needham, op. cit.,

392. The earliest printed illustration of this mechanism is in the Nung

Shu of 1313 A.D. See Needham, op. cit., 395.

On cams and camming action in general see Lynn White, 1962,

79, 81 and 128ff as well as Needham, op. cit., 83, 84 and 384-85.

Bloch, 1935, 543: "Un instrument de broyage qui, sur le plan,

n'était certainement pas mû par l'eau."

Munich, National Library, Ms. Cat. 197, fol. 10r. See Beck,

1899, 279ff. Cf. below, p. 248, n.67, on the date of the ms.

EVIDENCE FOR WATER-POWERED TRIP-HAMMERS

The Plan of St. Gall contradicts these views. The pilae

of its Mortar House can under no circumstances be interpreted

as vertical pestles. Their design—a hammer attached

at right angles to a pestle beam connecting at the opposite

end with a body of cylindrical shape—leaves no doubt

that they were recumbent hammers activated by the cams

of a revolving drum. Their dimensions as well as their

location, next to a water-driven grain mill, suggests that

they were water powered. The pestle beam alone is 10 feet

long (4 standard modules), the hammer has a length of 6

feet (2½ standard modules) and the drum has a diameter

of 6¾ feet. The over-all length comes close to 17½ feet. This

is a very heavy piece of equipment that could not possibly

be operated by hand or foot. The Plan may somewhat

exaggerate the dimensions of the drum,[516]

but it leaves no

452.A MODEL. FARMYARD DETAIL WITH FOOT-OPERATED TRIP-HAMMER. HAN DYNASTY, 206 B.C.-220 A.D.

IRRIDESCENT GREEN GLAZED POTTERY, 8¾ × 6 × 2½ INCHES

only within the context of a water-powered apparatus.

Marc Bloch's argument that water is not shown on the

Plan, does not militate against this conclusion. We have

shown in our chapter on omissions and oversights how

waterways, although nowhere in evidence on the Plan,

could be a determining factor in siting of facilities dependent

on this power source, and were therefore clearly a

possibility taken into account by the designing architect.[517]

The crushing mechanisms of the Mortar House of the

Plan of St. Gall are, as far as I can see, the earliest historical

evidence of the use of hydraulic trip-hammers in Western

Europe. Their appearance on the Plan makes it clear that

water-driven trip-hammers were, at the time when the

original scheme was drawn, i.e., in 816-817, considered

standard equipment of a paradigmatic Carolingian monastery.

There is no reason to presume that the inventor of the

scheme was also the inventor of the mechanism. The

system as such may, even in Europe, have been of considerably

greater age. It may have been diffused in Frankish

times from China, as the stirrup certainly was, as the two

forms of modern horse-harnesses probably were, and as

the mechanical crank may have been.[518]

Yet even that is highly doubtful. We have shown in our chapter on

the Scale and Construction Method Used in Designing the Plan that the

author of the original scheme of the Plan was acutely aware of the

realities involved in his scaling of objects. It is possible, nevertheless that

minor distortions were brought into the drawing when the Plan was

copied. Small objects tend to be drawn slightly enlarged as they are

traced. The odd dimension of 6¾ feet of the hammer head and drum may

in the original scheme have been 5 feet.

Lynn White, 1962, 1-2, 14-28, 139-46 (stirrup), 59-61, 67-69,

156-57 (harness) 79, 81, 128ff (crank). Needham, op. cit., 317 note e

(stirrup), 304-28 (harness), 111-19 (crank).

A SURVIVING MEDIEVAL HYDRAULIC TRIP-HAMMER

I feel strengthened in this conjecture by the circumstantial

historical evidence surrounding a water-powered

medieval trip-hammer that came to my attention, in the

summer of 1970, while travelling in the mountains of the

province of León in Spain. This mechanism, not only

intact but able to be operated, is housed in a smithy located

in the valley of Compludo, on the grounds of a former

monastery of that name. San Fructuosus, a Visigoth of

royal blood and the founder of Spanish monachism, established

Compludo as the first of a vast web of monasteries.

The trip-hammer owes its anachronistic survival to the

452.B

The processing of grain for domestic use

in China during the centuries just before

and after the birth of Christ in the West

reveals wholly familiar technologies and

associations. The model of the farmyard

(fig. 452. A) contains, in addition to the

trip-hammer, a small mill and what

appears to be a parching kiln built into an

enclosure wall—an association also

reflected in the Plan of St. Gall, some 6

centuries later.

The trip-hammer in the model (figs.

452.A-B) was the simplest of mechanisms;

in it is applied the principle of fulcrum

and lever actuated by direct force.

452.C

WILLIAM ROCKHILL NELSON GALLERY OF ART, ATKINS MUSEUM OF FINE ARTS, KANSAS CITY, MISSOURI

IRRIDESCENT GREEN GLAZED POTTERY, 10¾ × 3½ × 3½ INCHES

is accessible by only a stony mountain road whose narrow

and precipitous course offers to the unexpecting modern

visitors moments of breathtaking suspense.[519] The instrument

is described by Florentino-Augustin Diez Gonzáles,[520]

in a study of the political and social life of the Spain of San

Fructuosus, which also includes a sketch of this unusual

mechanism.[521] It conforms in all respects to the trip-hammer

shown in Spechtshart's woodcut of 1488 (fig. 455)

and the modern specimen discussed by Meringer (fig. 453),

except that it is considerably larger.

The water that sets the Compludo hammer into motion

is channeled from the confluence of two narrow mountain

streams, the Miera and the Miruello, into a collecting

basin (banzao) from where it falls upon the heavy wooden

studs of a waterwheel. This wheel, 8 feet in diameter, is

driven by a shaft (árbol) made of chestnut, 16 feet long

and 2½ feet thick. Rotating horizontally this timber,

hardened by age like stone, activates with its wooden cogs

452.D CHENGTU, SZECHUAN, PROVINCIAL MUSEUM

RUBBING, CLAY TOMB TILE, (46 × 28cm) DETAIL, EASTERN HAN PERIOD, 23-220 A.D.

[after Liu Chih-yuan]

Two men are shown pounding rice with trip-hammers, a scene of daily life of the lower social strata of Chinese society that artists of the

Eastern Han loved to portray.

The tile was excavated in 1956 at T'ai-p'ing-hsiang, P'enghsien, Szechuan Province. It was published in Ssu-ch'uan Han-tai hua-hsiang

pei-t'o p'ien (Portfolio of Han Dynasty Impressed Clay Tiles from Szechuan), Ssu-ch'uan sheng po-wu-kuan (Szechuan Provincial

Museum) by Shang-hai jen-min mei-shu ch'u-pan she (Shanghai People's Art Press), 1961, pl. 3, from which this detail is taken.

453. MODERN TILT-HAMMER (SCHWANZHAMMER)

PLAN AND SIDE ELEVATION

[redrawn after Meringer, 1907, 285, fig. 10]

The cam block driving the hammer can be linked to a drive system

as sophisticated as one powered by steam, or as simple as one driven

by an animal on a treadmill.

smashing hammer (mazo) rises and falls. The rhythm or

beat of the stamp can be controlled from within the forge

by a second mechanism that augments or decreases the flow

of the water turning the wheel, as the varying nature of the

work requires (sketched roughly in Gonzáles's drawing).

The ore is smelted in the furnace by a fire fanned to intense

heat by means of air drafted into it by hydraulic action

(shown in the background of Gonzáles's sketch) and under

the beat of the hammer, converted into malleable iron.[522]

To watch this primordial mechanism in operation was

truly an awe-inspiring experience.

The valley of Compludo lies in the Montes de León some 23 km.

southeast of the city of Ponferrada. It is not shown on the Mapa Oficial

de Carreteras (scale 1:400,000) of Spain. To reach it one must travel from

Pontferrada to the mountain villages of Molinaseca, Riego de Ambroz and

Acebo; and from the latter in precipitous descent (only advisable to

motorists with experience in rough mountain travel) to the completely

isolated valley of Compludo, formed by the confluence of two narrow

mountain streams, the Miera and the Miruello which shed their water

into the Boeza River. The scenery is of outstanding beauty.

Florentino-Augustin Diez González, "Notitias de la vida políticosocial

de la España de San Fructuoso," in San Fructuoso y su tiempo,

1966, 7-57.

The drawing in Gonzáles's article, while portraying operational

details of the smithy of Compludo with great veracity, is not quite

realistic in its perspective. The trip-hammer is not longer, but 3 feet

shorter than the tree by which it is activated and the diameter of the

waterwheel is greater than appears on the drawing (cf. Horn, 1975, 245).

I do not know at what time in history water pressure was first used

to blow air into furnaces. Lynn White, in a recent essay on "Medieval

Uses of Air" does not make reference to the existence of any such

systems (Lynn White, 1970, 92-100).

MONASTIC ECONOMY AND WATER POWER

UNDER ST. FRUCTUOSUS

The date of the hammer is unknown.[523]

Local tradition PERSPECTIVE VIEW [redrawn after Meringer, 1909, fig. 35] Meringer interpreted the two trip-hammers of the Mortar House of

ascribes it to "Romanesque period" (edad romanica).

454. PLAN OF ST. GALL. TILT-HAMMER

the Plan as being activated by a cam block formed on a single

timber extending, as part of an axle shaft, from the hub of the

waterwheel.

have been an integral part of the monastic economy of the

time of San Fructuosus (d. 665).[524]

This view is not so

455. SPECHTSHART. FLORES MUSICAE

STRASSBOURG, 1488, fol. 7v

[courtesy of the University Library, Freiburg i. Br., Germany]

The woodcut shows an iron forge with a water-powered tilt-hammer

activated by a cylindrical cam block mounted on the axle of a waterwheel.

Two blacksmiths forge iron on an anvil with the hammer's

aid; behind them Pythagoras weighs hammers. In the background,

Tubal chisels musical notes into a column, representing Pythagorean

philosophical preoccupation with order, number, and harmony of the

spheres of the Ptolemaic universe (cf. I, 231, fig. 187).

seventh century, as has been shown in the preceding

chapter, was the great century of systematic application of

water power to milling in the economy of coenobitic

monachism.[525] The development was spurred by the need to

provide great quantities of flour for the sustenance of large

numbers of men whose religious activities required that they

be freed from certain common forms of labor, in order to

devote themselves to the more serious task of serving God

in prayer and chant. It is not an unreasonable conjecture

that the same need may also have fostered the invention or

adoption of the cam which made it possible to harness water

for tasks requiring the crushing blow of a rising and falling

mechanical hammer. It is quite possible that this idea (or

its adoption) was first conceived in connection with iron

works where the brutal blow of a hydraulic stamp offered

advantages highly superior to those that could be derived

from its use in the lighter task of crushing grain or of

fulling cloth. The banks of the rivers in the mountains of

Eastern Leon, where San Fructuosus founded his first

monasteries, carry iron deposits important enough to be

mentioned by Pliny the Elder and other Roman writers;[526]

numerous localities in this area, now in ruins or deserted,

carry even today the name herrería (iron forge).[527]

The Fructuosan monastic economy formed an ideal

ambiance for the invention of such a power mechanism. It

created a sudden and vast demand for agricultural tools by

converting virtually overnight deserted valleys into densely

populated rural communities, formed not only by the

multitude of monks that settled in the monastery itself, but

in addition by a veritable army of secular followers who

were allowed to establish themselves as tenants in the vast

stretches of land which the monastery owned in the valleys

and mountains around it. Among them were members of

the former household of San Fructuosus (whose paternal

inheritance was enormous), magnates from the royal court

with their entire families, soldiers from the Visigothic

army who fell under the spell of the saint, and in a mystical

commotion that had no precedent, followed him in such

numbers that their chieftains found themselves compelled

to legislate against such wholesale desertion of the army

and flight into the country.[528]

A blacksmith capable of

converting ore into iron with the aid of water power and

shaping it into usable tools could meet the demands created

by such a sudden population increase in the country, and the

456. MUNICH, BAYERISCHE STAATSBIBLIOTHEK. MS. LAT. 197, fol. 10r

ATTRIBUTED TO AN ANONYMOUS ENGINEER OF THE HUSSITE WARS, CA. 1472-1486[529]

An annotation in Old High German explains the mechanism of this vertical-pestle stamp mill: "Item das is ain stampff damit man pulver

stost unn dye stampff gent all drey in ain loch, ainer auf der ander ab" (Item: This is a mortar for pounding powder, and all three pestles drop

into a hole, one after another).

VALLEY OF COMPLUDO, LEÓN, SPAIN. MEDIEVAL IRON FORGE & WATER-POWERED TRIP-HAMMER,

WITH FORGE BLOWER ASSOCIATED WITH FLUME. Date of the initial installation unknown,

concept possibly dating from Visigothic period. See caption above.

457.A

PERSPECTIVE VIEW

In 1975 we paid another visit to the Compludo

forge and discovered that the trip-hammer we

first inspected in 1970 was being rebuilt, and the

waterwheel replaced by a slightly sturdier one.

The hammer had been moved to the outside yard

to serve as a template for its replacement. The

sturdy cammed trunk, strongest member of the

mechanism and subject to great torsional strain,

was considered in good enough condition to serve

another span in the life of the hammer. It had

earlier been reinforced lengthwise by iron bars

banded to it with iron hoops.

The carpenter directing the work was convinced

that in continuous use, wheel and hammer would

need replacement every 40 years, the main trunk

every century. He shared local belief that the

mechanism is medieval and would tend to retain

its original design for a virtually indefinite span

of time, even though its components were

periodically renewed.

These drawings were made with aid of measurements

taken in 1975. They do not show the

apparatus governing the flow of water to the

wheel and thus the speed of the hammer's

action. For rough sketches of that mechanism

and the means by which air is drafted into the

forge furnace, a function also associated with the

flow of water to the wheel race, we still depend

exclusively on the drawing published by

Gonzáles (1966, 46) and reproduced by Horn

(1975, 245).

457.B

457.C

457.D

to the adoption of devices facilitating their production.

The Romans, it is generally conceded, did not make any

use of water-powered trip-hammers transmitting the

rotational movement of the wheel and its axle into the

vertical beat of a recumbent hammer by means of cogs.

China, unquestionably is the prime inventor. But the Plan

of St. Gall attests that at the beginning of the ninth century

such mechanisms were, even in the West, well known and

widely employed. This seems to vitiate the theory of its

westward diffusion by Marco Polo and suggests that the

knowledge of this invention came to Europe in the wake of

contact established with the Far East, in the fourth and

fifth centuries A.D. by the invasion of the Huns and other

Asiatic tribes, with whom the Visigoths were in close, and

often mortal, association over long periods of time.

In an earlier study (Horn, 1975, 254 note 13) I expressed the hope

that radiocarbon analysis of the timbers of axle, hammer, and waterwheel

might in the future help establish the age of the hammer. Returning to

the site in 1974, I discovered that all these timbers were in process of

being replaced. The carpenter in charge of the work held the view that

because of the heavy strain imposed upon these members when in daily

operation, such repairs would have to be made every 40 to 50 years. This

does not militate against the assumption of a medieval origin for the

mechanism on this site.

"La [herrería] de Compludo signe siendo un monumento vivo, casi

intacto, que bien pudo connocer los tiemposos frutusianos." Gonzáles,

op. cit., 44.

Gonzáles, loc. cit., lists one in the vicinity of Vega de Valcarce;

another one in Puente Petra (near Oencia); a third one in Marciel (near

Quintana de Fuseros) which gave its name, Ferreria, to a village that has

since disappeared; a fourth one in Paradaseca. In a fifth, the herreria of

Montes (near San Clemente de Valdueza) the stamping mechanism is so

well preserved as to permit its reconstruction.

For more detail on these historical conditions, see the chapter "Los

Pobladores del Valle," by Antonio Viñayo Gonzáles, in San Fructuoso y

su tiempo, 1966, 195ff.; as well as the chapter "La España rural des siglo

VII," by Florentino-Augustín Diez Gonzáles, ibid., 47ff.

FROM CHINA TO EUROPE DURING THE

MIGRATION PERIOD?

The display of water-powered trip-hammers on the Plan

of St. Gall gives added credence to such literary sources

as had been adduced by Bloch, Gille and Carus-Wilson[530]

in favor of the contention that hydraulic trip-hammers were

operated in eleventh- and twelfth-century Europe; as well

as the claim advanced by Uccelli and White[531]

that the fulling

mills of Prato made use of hydraulic trip-hammers from

the beginning of this industry in A.D. 983.[532]

An even

earlier reference (datable 883-904) to molinis vel pilis is to

be found in the Formulae Sangallenses miscellaneae.[533]

Bradford B. Blaine, in his forthcoming book, Water-Power in

Medieval Industry, focuses more intensely than has hitherto been done

on the profoundly significant industrial revolution, discernible by the

beginning of the eleventh century throughout the Alpine forelands,

involving the marriage of the waterwheel and the cam, as witnessed by the

appearance of water-driven hammers used for fulling, crushing hemp,

and forging iron (personal communication). The pilae of the Plan of

St. Gall disclose that this union was achieved considerably earlier (cf.

p. 235, n. 26 and my remarks, pp. 237ff).

Formulae Sangallenses Miscellaneae, Chap. 11, in Mon. Germ. Hist.

Leges, Sec. V, 1886, 385: Dedi itaque ego N. ad cellam sancti ill. villam

eidem loco vicinam . . . id est domibus, pomariis, exitibus et introitibus, viis,

aquis aquarumque decursibus, at clausuris, molinis vel pilis, agris, pratis,

silvis communibus aut propriis pascuisque in omnem partem vergentibus

mancipiisque, iumentis et peccoribus vel cunctis utensilibus. The passage was

brought to my attention by Bradford B. Blaine.

EUROPEAN SOURCES BEFORE MARCO POLO

A literary account of poetic beauty of water-driven

trip-hammers, written decades before Marco Polo's visit

to China (A.D. 1280), is to be found in a remarkable thirteenth-century

description of the waterworks of the monastery

of Clairvaux. There, after telling how the river Aube

had been deflected from its natural course, the writer

traces the water's path as it travels from workshop to

workshop, "launching itself at once upon the wheels of the

mill, and lashed into foam by their motion, it grinds the

meal under the weight of the millstones, and separates the

fine from the coarse by a sieve of fine tissue." Then, after

a brief excursion into the brewery, "where it fills the

boiler and is heated for brewing. . . not hesitating nor

refusing any who requires its aid," it follows the call of the

fullers, at whose workshop, close by the mill, "you may

see it causing to rise and fall alternately the heavy pestles,

that is to say, hammers or wooden foot-shaped blocks—for

that name seems to agree better with the treading-work, as

it were of the fullers—and so relieves them of the heaviest

part of their labor" (sed graves illos, sive pistillos, sive malleos

dicere mavis, vel certe pedes ligneos—nam hoc nomen saltuoso

fullonum negotio magis videtur congruere—alternatim elevans

atque deponens, gravi labore fullones absolvit. . .)[534]

Descriptio Monasterii Clarae-Vallensis, ed. Mabillon, II, 1690

cols. 1306-1309; and 4th ed., II:2, 1839, cols. 2529-33; reprinted in

Migne, Patr. Lat., CLXXXV, 1879, cols. 569-73, and in extract in

Mortet and Deschamps, II, 1929, 27-29. A translation of this text into

French may be found in D'Arbois de Jubainville, 1858, 329-88; into

English in Eales, 1912, 461-67.

TRIP-HAMMERS WITH VERTICAL PESTLES

There existed in the Middle Ages, as already mentioned,

yet another pounding mechanism making use of camming

action that cannot be overlooked in this context. It worked

with vertical pestles rather than with recumbent hammers.

Illustrations of these are found in the Mittelalterliche

Hausbuch of about 1480,[535]

in several manuscripts of

Leonardo da Vinci[536]

and in the manuscript attributed

to an anonymous Hussite engineer of around 1430 (fig.

456). Needham considers these vertical stamping mechanisms

"as characteristically European as the recumbent

tilt-hammer was Chinese."[537]

This may be true, but there

is no historical assurance whatsoever that in Europe the

invention of the former preceded the adoption of the

latter[538]

and any attempt to interpret the pilae of the Plan

of St. Gall, or the pistillos, sive malleos, vel certe pedes

ligneos of the thirteenth-century description of the water-powered

trip hammers of the Abbey of Clairvaux in the

light of this vertically operated pounding mechanism

would be straining the available historical evidence beyond

the limits of propriety. Amongst the vertical medieval

crushing devices listed by Needham, or anyone else

as far as I can see, there is not a single one with pestles

the shape of which could in any manner be compared

with that of a hammer (malleus) or a foot-shaped member

(vel certe pedes ligneos). A hammer, whether struck horizontally

or vertically, hits its object on impact, in a position

which places its longitudinal axis parallel to the surface

that receives its blow. It can accomplish this only with the

PLAN OF ST. GALL. MORTAR HOUSE. AUTHORS' INTERPRETATION

458.B

458.A

458.D

458.C

PLAN. TRANSVERSE SECTION, LONGITUDINAL SECTION; SOUTH ELEVATION

The Mortars of the Plan are here reconstructed as water-driven mechanisms, with their axle-trees oriented east and west and the presumptive

waterwheels to which these were geared oriented in the same direction, as are the waterwheels of the reconstructed Mill (above, fig. 448. A-E).

PLAN OF ST. GALL. AUTHORS' RECONSTRUCTION

458.E

458.F

WEST ELEVATION, NORTH ELEVATION

If a stream existed on the site and the land gradient permitted the development of waterpower, great efficiency could be achieved by this

alignment of the wheel races. For justification of water-powered mechanisms see above, p. 232, caption to fig. 448. In actual construction, we

believe such details would have been resolved by experienced craftsmen.

its longitudinal axis. In the vertical crushing mechanism,

illustrated by the anonymous Hussite engineer (1472-78),

the Hausbuch Master (ca. 1480) and Leonardo da Vinci

(turn of the fifteenth to the sixteenth century), the pestles

are pointed, i.e., pencil-shaped, and could not by any

stretch of the imagination be interpreted as "hammer-" or

"foot-shaped" instruments. There is no doubt in my mind

that the pilae shown on the Plan of St. Gall must be interpreted

as recumbent hammers. They have the shape of

hammers, and the presence of a drum at the end, which

lies opposite the head of the hammer, as well as their

dimensions, allows for no other interpretation.[539]

For detailed references to Leonardo's drawings of vertical crushing

mechanisms see Needham, op. cit., 395, note d.

It has been generally overlooked in this discussion that the same

anonymous Hussite engineer, who furnishes us with the earliest visual

representation of a vertical pestle stamp provides us also with an illustration

of a grain-crushing mechanism, operating with recumbent

hammers (Munich, National Bibliothek, Ms. lat., fol. 17v; see Beck,

op. cit. 278-80). I am drawing attention to this fact because there seems

to be a tendency, in the literature on this subject, to think that in Europe

the use of the vertical pestle stamp preceded that of mechanisms working

with recumbent hammers, because of the erroneous view that the former

is earlier attested in the visual arts. This would not only be a conclusion

highly questionable in itself, but also one based on mistaken facts. Both

instruments portrayed and described by the Hussite Engineer are hand-operated

and of rather light construction, made for home rather than

industrial use, and therefore not really comparable to the heavy equipment

shown on the Plan of St. Gall or described in the poetic thirteenth-century

account of the waterworks of Clairvaux.

The traditional date of Ms. Lat. 197, "ca. 1430" (Beck, 1899, 280;

Needham, IV:2, 1965, 395; Horn, Journal of Medieval History I, 1975,

244) must be revised. Lynn White informs us that Bert A. Hall, in an

unpublished dissertation "The so-called `Manuscript of the Hussite Wars

Engineer' and its Techological Milieu: A Study and Edition of Codex

Latinus 197, Part 1," University of California, Los Angeles, 1971) showed

conclusively that it is two manuscripts bound together. They are from

the hands of two engineers, neither of whom can be shown to have had

any involvement in the Hussite Wars. Folios 1-28 can be dated to ca.

1472-1485, folios 29-48 to ca. 1485-1496.

It has been generally overlooked in this discussion that the same

anonymous Hussite engineer, who furnishes us with the earliest visual

representation of a vertical pestle stamp provides us also with an illustration

of a grain-crushing mechanism, operating with recumbent

hammers (Munich, National Bibliothek, Ms. lat., fol. 17v; see Beck,

op. cit. 278-80). I am drawing attention to this fact because there seems

to be a tendency, in the literature on this subject, to think that in Europe

the use of the vertical pestle stamp preceded that of mechanisms working

with recumbent hammers, because of the erroneous view that the former

is earlier attested in the visual arts. This would not only be a conclusion

highly questionable in itself, but also one based on mistaken facts. Both

instruments portrayed and described by the Hussite Engineer are hand-operated

and of rather light construction, made for home rather than

industrial use, and therefore not really comparable to the heavy equipment

shown on the Plan of St. Gall or described in the poetic thirteenth-century

account of the waterworks of Clairvaux.

The traditional date of Ms. Lat. 197, "ca. 1430" (Beck, 1899, 280;

Needham, IV:2, 1965, 395; Horn, Journal of Medieval History I, 1975,

244) must be revised. Lynn White informs us that Bert A. Hall, in an

unpublished dissertation "The so-called `Manuscript of the Hussite Wars

Engineer' and its Techological Milieu: A Study and Edition of Codex

Latinus 197, Part 1," University of California, Los Angeles, 1971) showed

conclusively that it is two manuscripts bound together. They are from

the hands of two engineers, neither of whom can be shown to have had

any involvement in the Hussite Wars. Folios 1-28 can be dated to ca.

1472-1485, folios 29-48 to ca. 1485-1496.

RECONSTRUCTION OF PILAE ON THE

PLAN OF ST. GALL

Using as a model the trip-hammers of the iron forge of

Spechtshart's Flores Musicae (fig. 455), the trip-hammer of

the monastic smithy of Compludo (fig. 457), and the modern

example described by Meringer (fig. 453), we have reconstructed

the mortars of the Plan of St. Gall as water-driven

crushing hammers whose movement is controlled by the

cogs of a cylindrical drum mounted directly upon the axis

of a waterwheel (fig. 458).

DIETARY IMPORTANCE OF CRUSHED GRAIN IN

WESTERN EUROPE

The amount of crushed grain used daily in a medieval

monastery must have been considerable. A mixture of

barley and oats, made into a kind of porridge or "pap" by

the crushing action of the mortar was a chief item in the

diet of the people of Western Europe prior to the introduction

of the potato. The German word for this dish is mus,

and in the monastery of St. Gall the use of this term, as

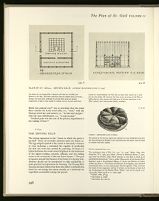

459.A PLAN OF ST. GALL. DRYING KILN. AUTHORS' RECONSTRUCTION [1:192]

The shelter for the Drying Kiln is identical with those for the Mills and

Mortars of the Plan. This house could have been the simplest kind of structure,

perhaps even open-sided. Although the Drying Kiln would not develop

temperature so high as those needed for baking, some fire hazard would have

existed in a closed building; the Plan does not show either smoke exit or stack

port for this facility. We reiterate that these service structures of the Plan are

highly abstract; their purpose and siting were of foremost importance to the

Plan's makers; their constructional details, secondary.

Kero renders the Latin word cibus, i.e., "food," with the

German word mus, and caenare, i.e., "to take one's supper,"

with the term abendmussen, i.e., "to sup on pap."

Crushed grain was also one of the primary ingredients in

the making of beer.[541]

V.15.4

THE DRYING KILN

The drying apparatus in the "house in which the grain is

parched" (locus ad torrendas annonas) need not detain us.

The egg-shaped symbol in the center is obviously a furnace

or oven enclosing a contained fire capable of producing

the slow and even heat needed for parching. Its form is a

hybrid between the ovoid corner fireplaces in the bedrooms

of the higher-ranking monastic officials, and the baking

ovens in the monastery's bake and brew houses.[542]

The grid

of squares around this furnace is the frame of a drying rack.

Annonas should not be interpreted to refer exclusively to

grain parched in preparation for brewing. The Drying Kiln

was also the place where fruit from the abbey's orchards was

dried for use during the winter months as a substitute for

vegetables unavailable during this period.

459.B

POMPEII. CARBONIZED LOAF OF BREAD

The division of the loaf into equal-sized segments for easy distribution may have

had some relevance for Benedict's later instruction that the monks' ration of bread

be carefully and fairly weighed.

460. POMPEII. ROMAN ATRIUM HOUSE

[redrawn after Kahler, 1960, 163, fig. 80]

BAKING ESTABLISHMENT WITH LIVING QUARTERS

The layout combining living quarters with a commercial and industrial establishment,

shows Roman planing at its best. The forward part of the building is the

traditional Roman atrium house—descendant of a long lineage of Near Eastern and

Greco-Roman courtyard houses (cf. above, p. 6ff) which are as characteristically

Mediterranean as the aisled and bay-divided timber hall, from which guest and

service structures of the Plan descend, are Northern (cf. above, p. 23ff).

On the street front, to left and right of the entrance (1) are two three-room shops

(2, 3, 4; 5, 6, 7) unconnected with the interior. From the atrium (8) two stairs (9)

lead to the balcony giving access to an upper tier of rooms. To the left and right are

two cubicles (10, 11, 12, 13).

The rear part of the house, accessible through a fore room (14), which under normal

conditions would serve as tablinum, accommodates in an area of 8 × 10.2m (15)

four mills of the type shown in fig. 441, with paved walking strips for the donkeys.

Remaining rooms are: (16), a donkey stable with water trough; (17) a baking oven;

(18) a room for kneading and shaping dough; (19) a room for cooling bread; (20) a

bedroom for the mill slave, or kitchen (?).

| The Plan of St. Gall | ||